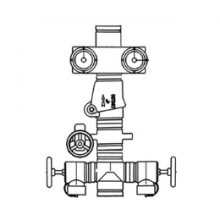

H-Pattern Fire Hydrant Booster Assembly

FFS-(size DN)MMHSB

- Booster assemblies are manufactured to conform to the requirement of AS2419 & to relevant local authorities. All components comply to the requirements of AS2419.

- Any fabricated components are Hot Dipped Galvanised as required in AS2419.

- Backflow prevention devices can be supplied and designed into assemblies. Backflow devices comply to AS2845.1.

- All components will withstand pressure testing up to 2100kpa. (Note: Fire Brigade test pressure is 1700kpa.)

- All booster units can be supplied as individual components or fully/ part assembled.

- Please nominate connections, LH or RH entry & either butterfly or gate valves required to suit relevant authority requirements.

Specification Sheets

Specification Sheets

Description

OPTIONS

- All assemblies can be custom built to comply with AS2419 where confined space is a problem.

- Copamate Flanges, Roll Grooved Flange Adaptors, Copper to RG Adaptors, Copper Long Leg Riser Elbows

- Hydrant booster cabinets are available for all booster configurations.

- Available in DN100, 150, 200 & 250.

- Please note: CAD drawings available on request.